The Advantages and Disadvantages of Fused Deposition Modeling (FDM) 3D Printing

3D printing is an additive manufacturing process that creates a physical object layer by layer based upon a CAD design or three-dimensional digital model. The first 3D printers appeared in the 1980s. These first printers were very crude; subsequent technological advancements have transformed 3D printing into a viable manufacturing option for several industries. Today, 3D printing is utilized by a number of sectors, including the aerospace, automotive, computer, manufacturing, defense, medical and consumer products industries.

Fused Deposition Modeling (FDM)

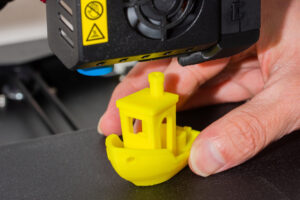

There are many types of 3D printing. By far the most popular type of 3D printing is Fused Deposition Modeling, also known as FDM. The FDM process uses heat to melt a filament of thermoplastic feedstock material. The most common feedstock materials used in FDM are polylactic acid (PLA) and acrylonitrile butadiene styrene (ABS). The molten filament is fed through an extruder and deposited layer upon layer via a spray nozzle to create a three-dimensional object.

FDM 3D Printing is an excellent choice for functional prototypes and end-use parts. It is utilized for production, concept models, manufacturing tools, and rapid prototyping. Some of the more common FDM applications include:

- Custom automobile parts

- Spare and replacement automobile parts

- Presurgical models

- Prosthetics

- Aerospace components

- Computer hardware

- Eating utensils, drinking utensils, and other household items

- Scale models and props

- Marketing swag

- Toys and gifts

What Makes FDM 3D Printing So Popular?

FDM is popular because it offers many advantages over other types of 3D printing. Some of these advantages include the following:

- A wider range of filament materials is available for use.

- FDM is faster than other types of 3D printing, allowing rapid turnaround times for finished parts and assemblies.

- It’s more inexpensive compared to other 3D printing methods.

- FDM produces more durable pieces; ideal for parts used in harsh environments.

- FDM can handle projects with very large pieces and complex geometries, usually at lower cost-to-size ratios than other methods.

- High-precision production with consistent and repeatable results,

- A completely toolless manufacturing; a printer is all that’s needed to create a part.

- Eco-friendly.

Some Drawbacks to FDM 3D Printing

While FDM provides many benefits, there are some disadvantages. FDM-printed parts often have a lower resolution and rougher finishes than those created using stereolithography (SLA) and other types of 3D printing.

Industrial FDM 3D Printing in Houston, TX

Located a few miles North of Houston in Conroe, TX, ProTek Models & 3D Printing is a leader in the field of industrial 3D print services. We offer our clients a wide range of services, including industrial FDM and SLA 3D printing, as well as RTV molding and custom scale model construction. Our client list includes businesses and organizations such as Boeing, Raytheon, Oceaneering, NASA, Mitsubishi, Google, Circor Energy, and the US Air Force.

Contact ProTek Custom Models and 3D Printing to learn how FDM and SLA 3D printing can benefit your business. You can reach us through our website or call us at (832) 968-6636 to speak to a member of our engineering team and receive a free quote.