- (832) 968-6636

3D Printing

FDM 3D Printing

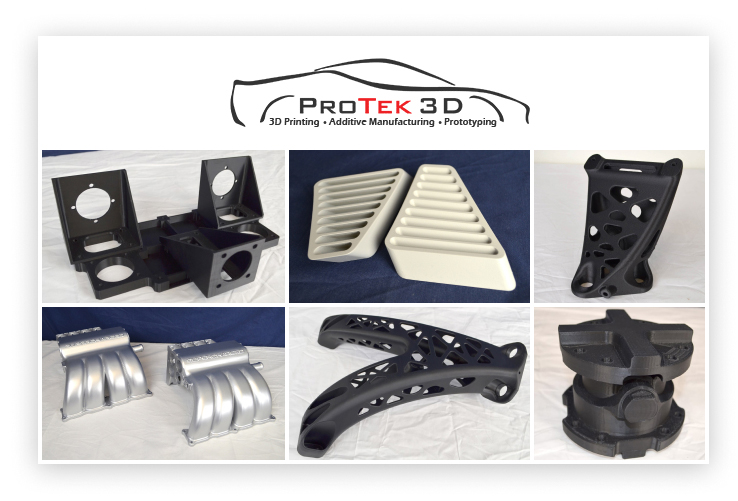

3D Printing - Additive Manufacturing - PrototypingFDM (Fused Deposition Modeling) 3D Printing offers a large variety of engineering grade thermoplastic materials, high precision, and rapid turnaround for your parts and assemblies. Utilized for production, concept models, manufacturing tools, and rapid prototyping, FDM 3D Printing is a great choice for functional prototypes and end use parts. FDM 3D printing can handle projects with very large parts and complex geometries.

ProTek 3D, the 3D printing division at ProTek Models, offers high quality FDM 3D Printing services. We offer every production-grade 3D printing material on the market, and by utilizing our Fortus F900, 900mc, 450mc, 400mc, and 360mc machines, our highly experienced team is able to tackle any assembly regardless of complexity or size.

SLA 3D Printing

3D Printing – Additive Manufacturing - PrototypingSLA or Stereolithography was the original 3D printing technology invented in 1989. Historically SLA has been known for great surface finish, high accuracy, fine detail, and fairly fast build times. SLA parts were also infamous for being very fragile, heat-sensitive, brittle, and very UV unstable. The drawbacks to this process made it a technology that was not used by ProTek Models until 2021. New, highly advanced production-grade resins have made their way to the market, and a new ultrafast SLA-type technology called LSPc (Lubricant Sublayer Photo-curing) was invented by NEXA3D. The ultrafast print speeds and production end-use quality materials are extremely exciting to all of us here at ProTek Models. We are now offering prototype and production 3D printing with NEXA3D NXE400 3D printers with the full range of NEXA3D prototypes and production-grade materials. We are also a reseller of the full production line of NEXA3D printers. With ultra-fast print speeds up to .393” (1cm) in the Z-axis and materials like xPEEK with a heat deflection temperature of 460F (238C), no other resin 3D printing technology comes close.

Recently, 3D Printing has become a game-changer in the automotive industry. With 3D Automotive Printing, there is a large portfolio of engineering grade plastics, large build envelopes, and a variety of resolution options that make it possible to FDM 3D print every part of an automobile. Bumpers, dashboards, consoles, seats, headlight assemblies, and more are no problem for the Stratasys Fortus 3D printers run by the skilled technicians at ProTek Models.

Our experienced team can print parts for prototypes and production parts intended for permanent use on race cars, road cars, trucks, and other automobiles. High-performance materials like Ultem 1010, Ultem 9085, and Nylon 12CF even make it possible to print production engine parts including engine manifolds and intercoolers used for dyno testing and low volume production applications. Low volume production FDM 3D printed bumpers, splitters, spoilers, diffusers, dashboards, consoles, and most other car parts can also be produced in a variety of high-performance engineering plastics.

With the skilled team at ProTek Models, there is no automotive part or model that we can’t handle.

The ProTek Models Difference

We go above and beyond with our 3D Automotive Printing. FDM 3D printed parts requiring watertight qualities are epoxy sealed twice by skilled ProTek Models technicians. This not only makes the parts watertight but further increases the strength of the parts. 3D printed parts can also be sanded, painted, textured, upholstered, chrome-plated, etc., depending on your specifications. All of these services and more are offered by ProTek Models, making us truly a one-stop-shop for all your FDM 3D Automotive Printing needs.

Applications of 3D Printing in the Automotive Industry

When it comes to 3D Printing in the automotive industry, there are many applications. These include:

- Design and Concept: With high-detail, extremely accurate 3D printed scale models, you can demonstrate designs and concepts of new vehicles. This goes beyond what CAD models can offer and also allows you to test the aerodynamics of new designs.

- Validation of Prototypes: Prototyping is essential in the automotive industry. With 3D Automotive Printing, you can validate prototypes of all types and sizes.

- Preproduction Sampling and Tooling: You can utilize 3D Automotive Printing to make molds and tools, jigs and fixtures. This allows you to produce samples at low costs, which can eliminate future production losses when it comes time to invest in high-cost tooling.

- Customized Parts: If you need to create customized or unique parts, 3D Automotive Printing allows you to do that in a quick, low-cost manner.

Benefits of Automotive 3D Printing

Automotive 3D Printing offers numerous benefits. With Automotive FDM 3D Printing, you can avoid expensive and long lead-time CNC production. 3D automotive printing is cheaper than CNC production and production is much shorter, especially when utilizing ProTek Models for your Automotive 3D Printing needs. Another production benefit of Automotive 3D Printing is that it creates less waste and allows for lower material consumption throughout the manufacturing process.

In addition to production benefits, 3D printing also allows designers the ability to try multiple options and iterations when creating new parts or models. With increased flexibility, auto manufacturers can create efficient designs quickly and affordably. This not only improves overall performance, but it can also provide a competitive advantage over the competition.

Contact Us To Start Your Automotive 3D Printing Project Today

If you want to get started with your Automotive 3D Printing project today, contact ProTek Models. Our knowledgeable team will work with you every step of the way to ensure the end result meets your specifications, timeline, and budget.