- (832) 968-6636

FDM 3D Printing in Yorba Linda CA

You Need a Company with Experience for FDM 3D Printing in Yorba Linda CA

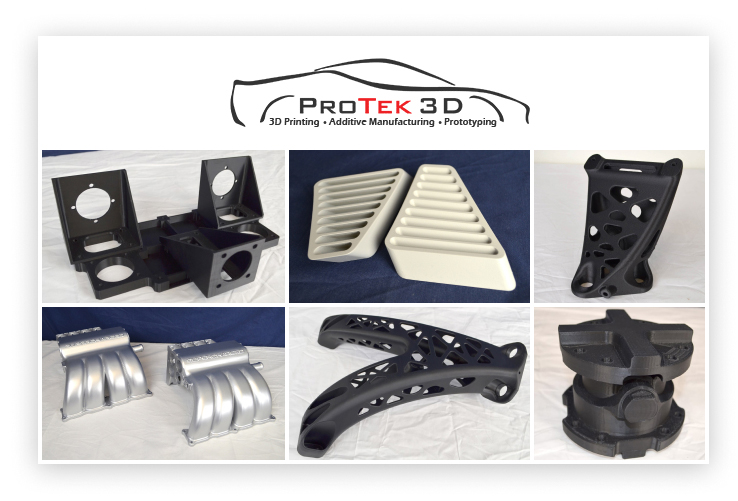

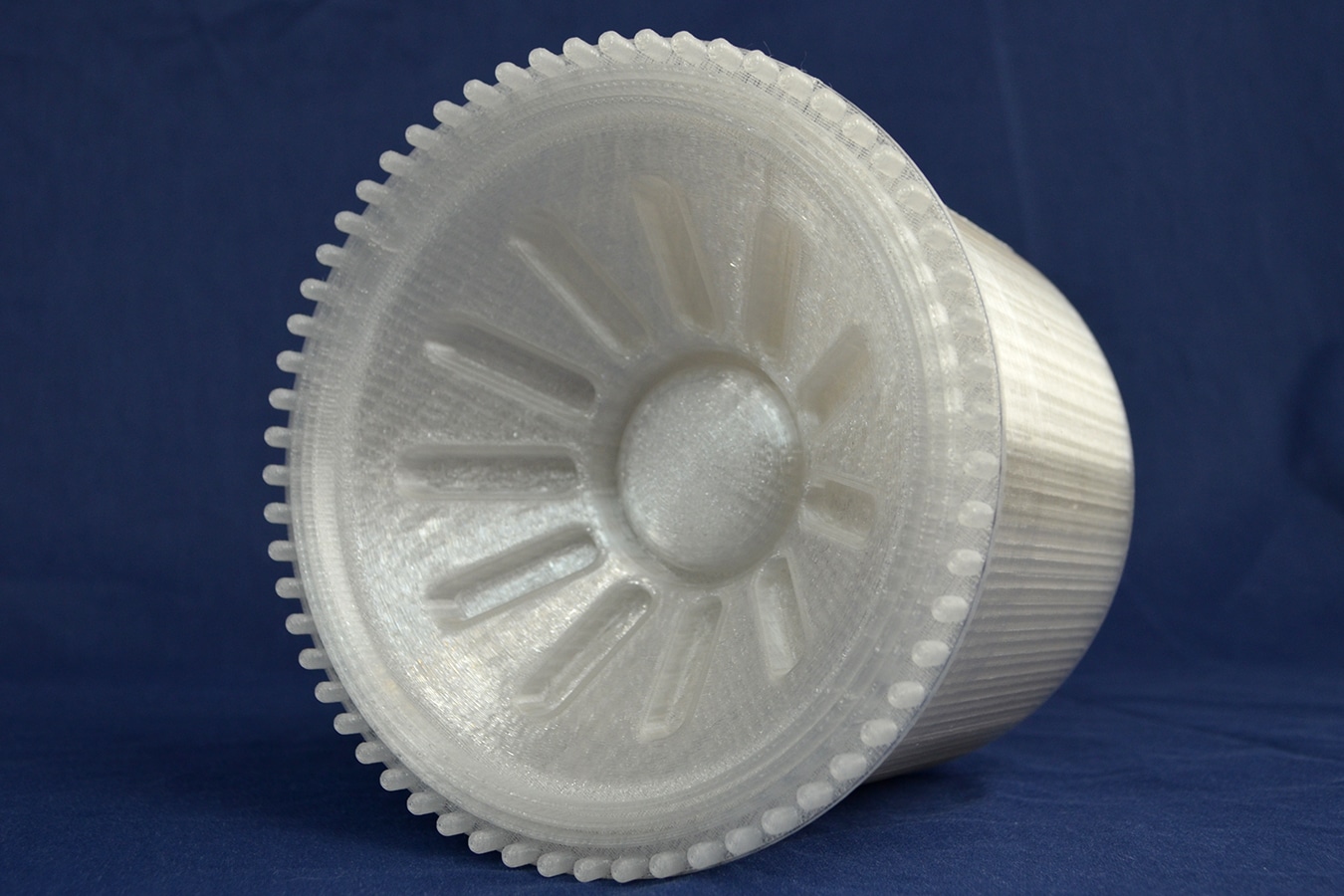

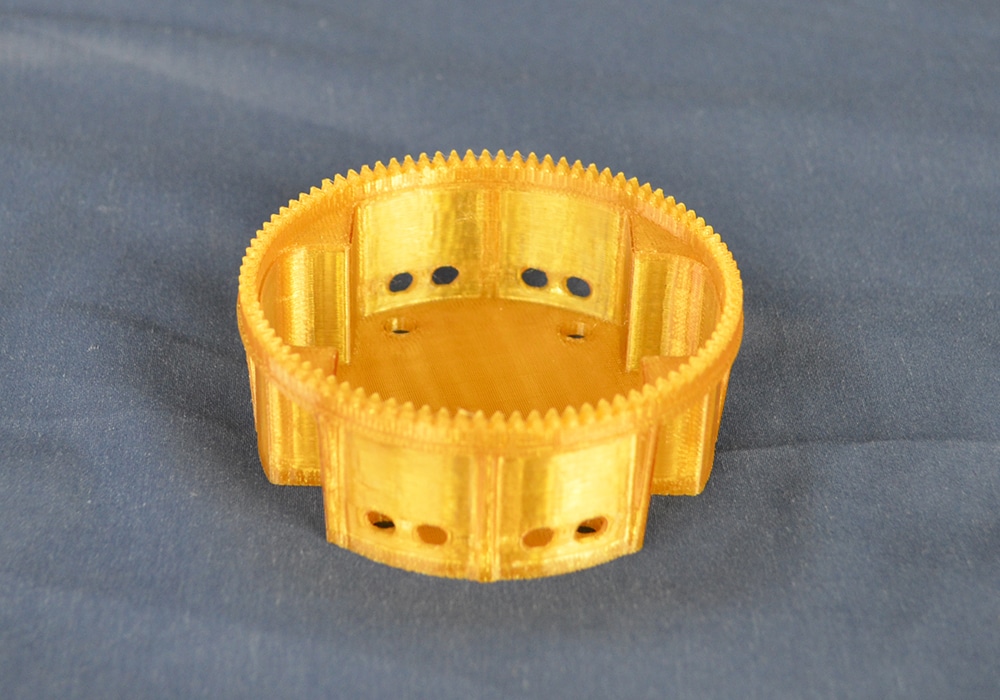

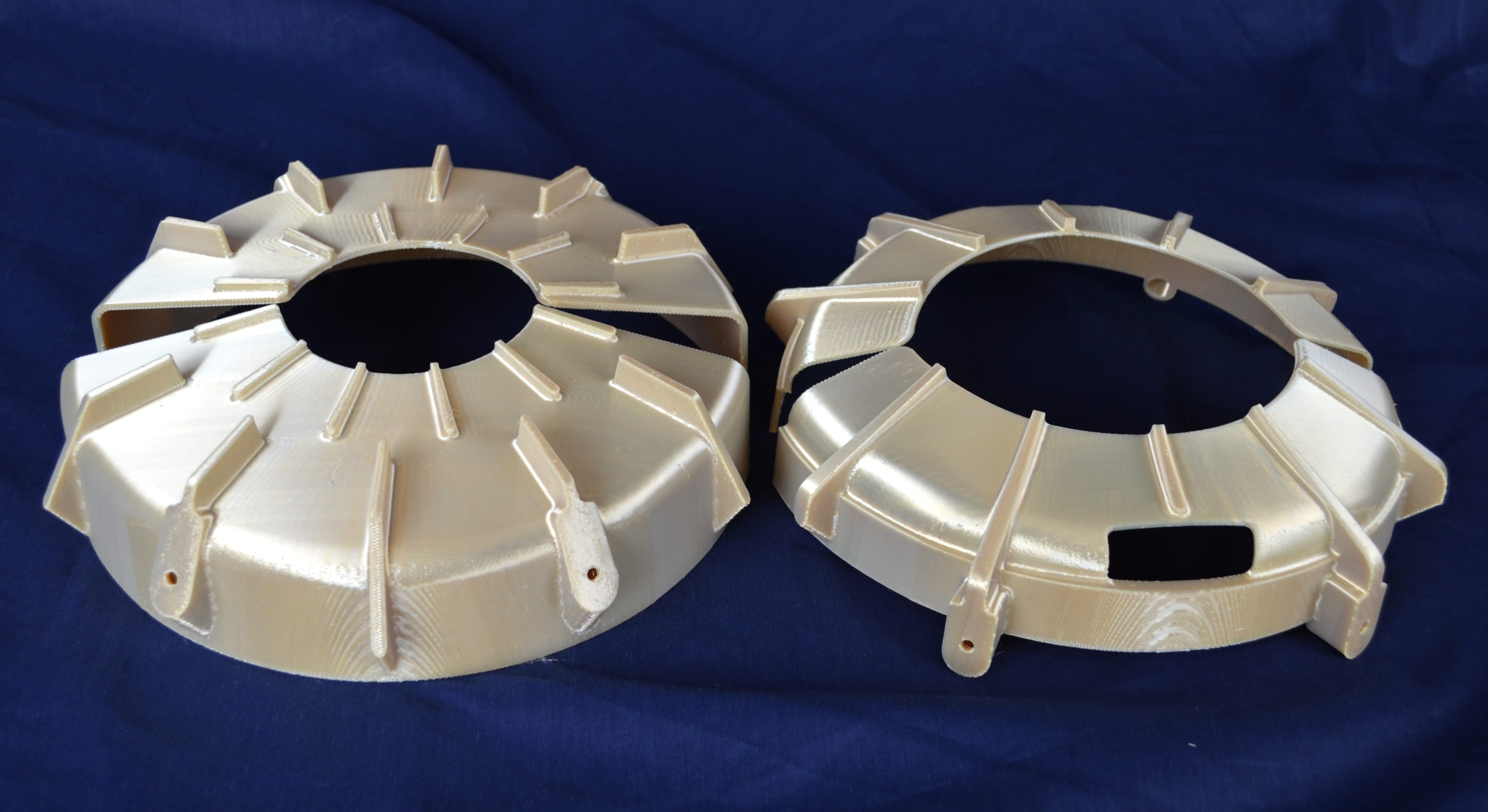

Is it true that there are more companies investing in the materials to provide services related to FDM 3D printing in Yorba Linda CA? Yes – but it is also true that many of these companies simply buy the equipment, read the manual, and profess themselves to be experts. This is not the case with ProTek Models. We have completed many projects, complete almost everything in-house and work with just about every material you can imagine. Trust us with your 3D printing project. Call us at (832) 968-6636 to get started.

It’s Essential to Choose In-House Services for FDM 3D Printing in Yorba Linda CA

If you are going to choose FDM 3D Printing in Yorba Linda CA, you want to ensure that it is actually going to be done by the company you hire. If you choose a company that then sends the work on to another company, you will both be paying an unnecessary markup and reducing your ability to control how the project goes. Work with ProTek Models, a company that does almost all of our work in house.

You Won’t Find a Project Involving FDM 3D Printing in Yorba Linda CA That We Can’t Handle

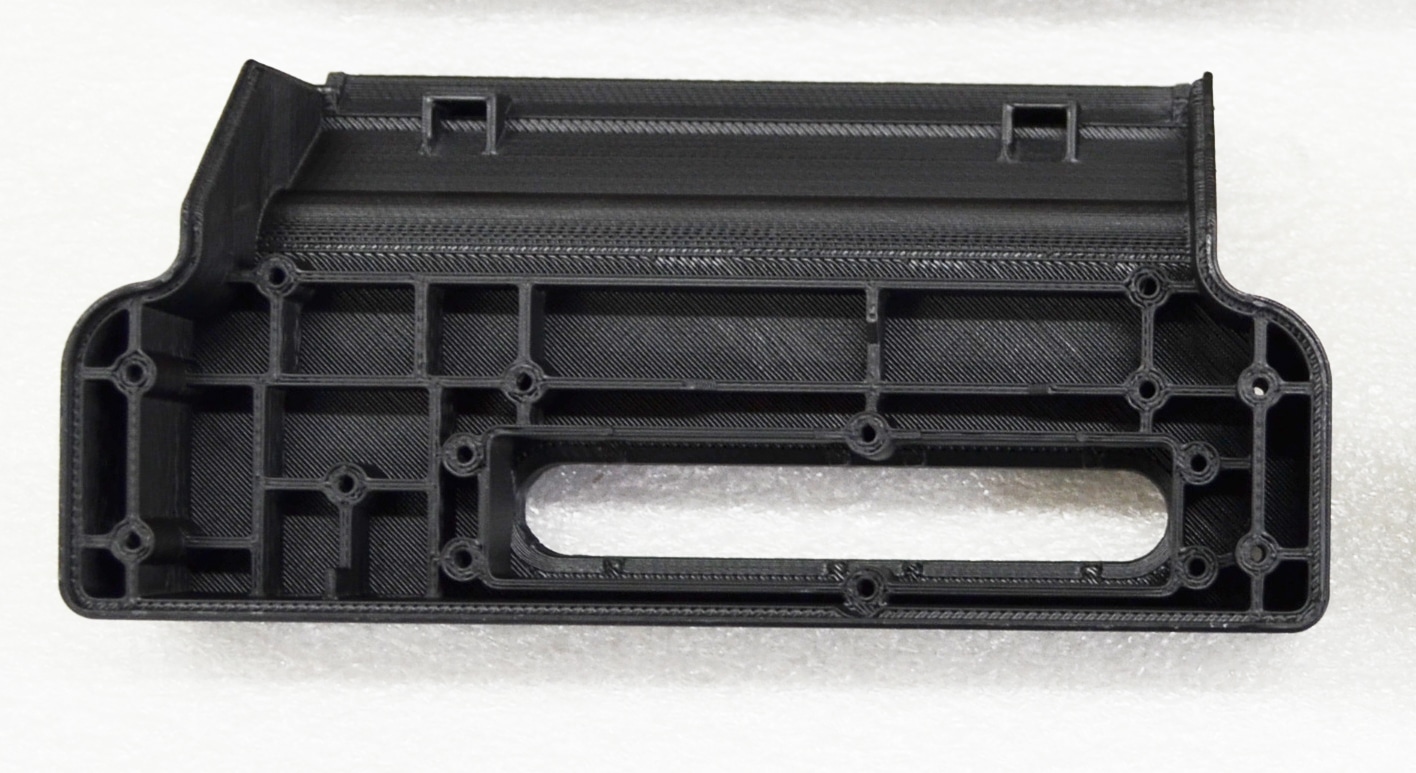

- Large and complex assemblies – this is not limited by any machine’s build envelope

- Post-processing including sanding, sealing, media blasting, priming, painting, and more

- Mold making with silicone or composite models, or even resin or composite

- Drilling

- Reaming

- Tapping

- Thread inserts

- Composite reinforcement

Are you in need of help with a type of project or material you do not see listed? Give us a call – it is likely we can help.

The 3-Step Process of FDM 3D Printing in Yorba Linda CA

There is a three-step process on every FDM 3D printing job we complete. In essence, it builds the parts of the product layer, starting with the bottom. The three-step process is this:

- Pre-Processing. This involves build-preparation and positioning the 3D printer.

- Production. This is the step in which the actual product is made.

- Post-processing. If other steps are necessary, such as filing, sanding, etc., we take care of it post-processing.

Every job is different but these are the three steps involved in most jobs.

Call Right Now to Learn More About Your Options for FDM 3D Printing in Yorba Linda CA

There is no better time to contact ProTek Models than right now. Our experienced and friendly associates are standing by to take your call – just reach out at (832) 968-6636. We are here to answer your question, get your order started, or help you better understand your options.

The ProTek Models

Difference

At ProTek Models, We are committed to providing our customers with the highest quality 3D printed parts and service.

quality FDM 3D Printing services

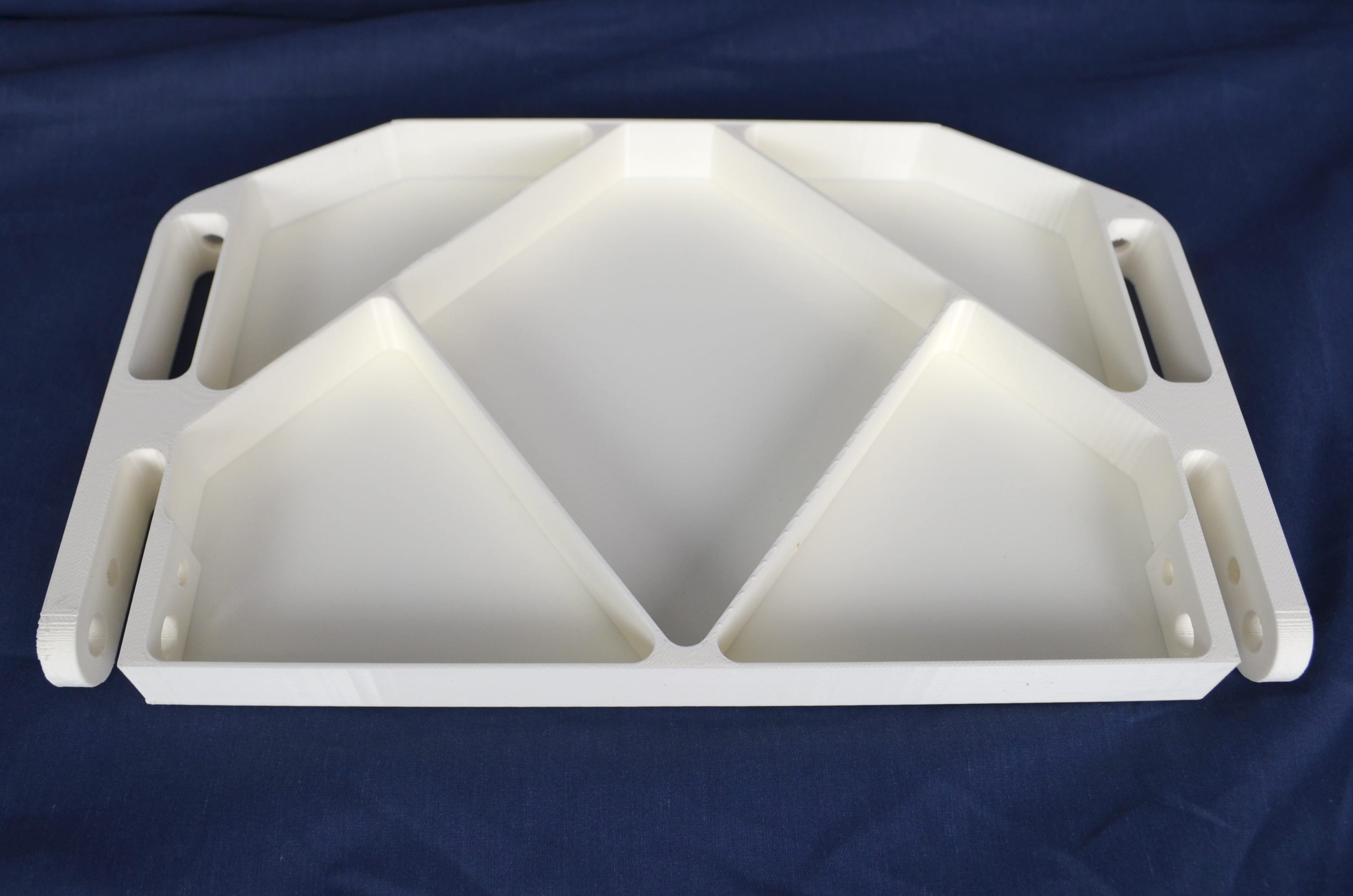

- Prototypes and production of small parts to very large and complex assemblies

- Numerous post-processing services available

- Composite renforcements (fiberglass and carbon fiber)

- Complex bonds, drilling, reaming, tapping, thread inserts

- Mold making for silicone or composite models for resin cast and composite parts

Materials We Offer

Choosing the right material for your FDM 3D Printing project is essential. At ProTek Models, we offer a wide variety of materials to choose from to ensure the parts we produce meet your requirements. Our FDM 3D printing experts can help you determine the best material for your application.

ABS-ESD7 prevents a buildup of static electricity so it will not produce a static shock or cause other materials like powders, dust, and fine particles to stick to it. Ideal for electronic products with circuit boards and for the transportation and industrial equipment industries. ABS-ESD7 is perfect for FDM 3D printing of parts that will come in contact with sensitive electronics.

Download Datasheet

ABS-M30 material is ideal for prototype and light-duty production parts including concept models, jigs, fixtures, manufacturing tools, and production parts. ABS M30 is stronger than traditional 3D printed ABS parts.

Download Datasheet

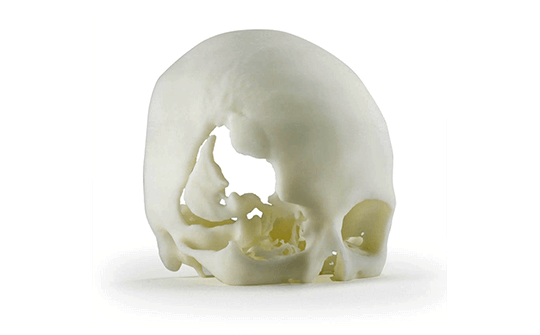

ABS–M30i is a biocompatible 3D printing material perfectly suited for medical, pharmaceutical, and food-packaging engineers and designers to produce surgical planning models, tools, and fixtures.

Download Datasheet

Antero 800NA – PEKK is the newest high-performance, engineering thermoplastic FDM material available on Fortus production 3D printers. Antero 800NA is a very high-performance FDM 3D printing material that offers excellent mechanical properties and low outgassing characteristics of PEKK material. FDM 3D printing with PEKK gives you design flexibility not possible with other fabrication methods. Antero 800na is an outstanding choice for parts requiring high-temperature resistance, long-term chemical resistance, high strength, and toughness.

Download Datasheet

ASA (Acrylonitrile Styrene Acrylate) is a UV-stable, production-grade thermoplastic. ASA has very similar properties to ABS-M30 and is an outstanding material choice for production and prototype parts. It has the best aesthetics of any FDM material. ASA is excellent for outdoor-use production parts due to its strength, color choice, and UV resistance.

Download Datasheet

Nylon 12CF is a high-performance FDM 3D printed thermoplastic material that has added fibers to improve its material properties. These fibers are used to improve the strength, stiffness, and thermal properties of FDM 3D printed parts. Nylon 12CF is an outstanding choice for FDM 3D printed parts requiring stiffness, strength, and overall toughness.

Download Datasheet

FDM Nylon 6 is a production-grade thermoplastic that combines the strength and toughness of Nylon 6 with the dependability and durability of FDM 3D printing. FDM 3D printing with Nylon 6 gives you tremendous design flexibility for your additive manufactured tools, prototypes, and production parts.

Download Datasheet

FDM 3D printed Nylon 12 is production-grade thermoplastic that is an excellent material for production and prototype 3D printing. Nylon 12 is very tough with just enough flex. FDM Nylon 12 combines strength with excellent fatigue properties suitable for repetitive closures, snap fits and vibration-resistant parts. Nylon 12 uses a water-soluble support so there are virtually no limitations to the complexity of your parts.

Download Datasheet

PC (polycarbonate) is a production-grade thermoplastic that is excellent for automotive, aerospace, medical, and many other applications. FDM printed PC parts offer high accuracy, durability, and stability, creating strong parts that withstand functional testing and end-use parts. Not only is polycarbonate extremely tough and durable, but it is also very resistant to temperature. This material is malleable when cool and can bend without cracking.

Download Datasheet

PC–ABS is a high-impact engineering thermoplastic ideal for functional prototyping, tooling, and low-volume manufacturing. Get the best of two FDM materials, the strength and heat resistance of PC and the flexibility of ABS. PC–ABS also delivers excellent feature definition and surface finish.

Download Datasheet

PC–ISO is a bio-compatible FDM thermoplastic that lets engineers create prototypes, molds, and products in a heat-resistant material for the pharmaceutical, food packaging and medical industries.

Download Datasheet

Engineered and tested specifically for sacrificial/washout tooling for composite fabrication. ST-130 withstands the heat and pressure of autoclave curing and it 3D prints with a permeable triangle fill pattern designed to optimize build speed, conserve material, and dissolve quickly.

Download Datasheet

ULTEM 1010 resin is one of the strongest FDM thermoplastics. Ultem 1010 3D printed parts have high heat resistance and thermal stability. It’s able to withstand autoclave operations and sterilization. It is an outstanding material option for composite fabrication tooling and parts that need high strength and heat resistance.

Download Datasheet

ULTEM 9085 resin features a high strength-to-weight ratio, high thermal and chemical resistance, and flame, smoke, and toxicity (FST) ratings. Ultem 9085 is FAA approved for aircraft interiors. Ultem 9085 is an excellent 3D printing material choice for production and prototype parts. ULTEM 9085 is a great FDM 3D printing choice for parts requiring high heat, chemical and flame resistance, high dielectric strength, thermal conductivity, and overall strength.

Download DatasheetWatch 3D Printing In Action