ProTek Models Offers EcoFriendly 3D Printing to Houston, TX Businesses

Businesses in Houston and elsewhere are looking for more sustainable, environmentally friendly ways to produce their products. In many instances, 3D printing has less of an environmental impact than other manufacturing processes. In this post, we’re going to take a look at some of the eco-friendly advantages 3D printing has to offer.

Reduced waste

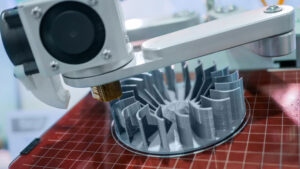

CNC and other traditional subtractive manufacturing processes produce a part by removing materials from a workpiece through cutting, grinding, and other means. These methods often result in significant waste. On the other hand, 3D printing is an additive manufacturing process. Pieces are built layer by layer, using the exact amount of material needed, greatly minimizing material wastage (and reducing overall costs).

Local Production

3D printers make it possible to manufacture on-site or locally. This reduces the need for long-distance shipping and transportation as well as carbon emissions and the environmental impact of packaging materials. Without transportation expenses, manufacturers can realize more profit from their products.

Print on Demand

3D printing is ideal for small to medium production runs. This reduces the amount of material and energy needed to manufacture a part, especially when compared to other manufacturing processes. Another advantage is that products can be printed to order, eliminating the costs and hassles of maintaining large stores of inventory.

Design Optimization

3D printing can produce parts with intricate geometries and complex designs that aren’t possible with other manufacturing processes. 3D printing can be used to create optimized, lightweight parts that can improve performance and energy efficiency by reducing weight and drag.

Sustainable Print Materials

PLA (polylactic acid), ABS (acrylonitrile butadiene styrene), and PVA (polyvinyl alcohol) are just three of the many biodegradable, eco-friendly thermoplastic materials available for use in the production of 3D printed parts. In many instances the waste material generated during the 3D print process can be reused, further reducing both environmental impact and overall costs.

Longer Lasting Products

3D printing can be used to create a wide range of replacement parts, reducing waste by extending the lifespan of products currently in use. This helps conserve resources, reduce energy use, and saves on repair and replacement costs.

In addition to being more environmentally friendly, 3D printing is often cheaper and faster than traditional manufacturing methods.

Are There Any Environmental Drawbacks to 3D Printing?

While 3D printing offers many environmental benefits it’s not without drawbacks. 3D printing can consume more energy than other manufacturing methods. In addition, the production, storage, and disposal of the plastics, resins, and other materials used in the 3D printing process can have a negative environmental impact. The good news is, advancements in 3D printing technology and thermoplastic media are addressing many of these problems.

Sustainable 3D Printing in Houston, TX

Sustainability is becoming an important factor for a growing number of local businesses when it comes to the design and manufacture of parts. ProTek Models and 3D Printing is here to help your business achieve its sustainability goals.

Located just a few miles north of Houston in Conroe, TX, ProTek Models is a leader in 3D printing, custom modelmaking, and urethane castings. We serve businesses all over the Houston area and throughout the Lone Star state. We have the experience and technology to tackle just about any 3D print project including rapid prototyping, small to medium production runs, customized parts, replacement parts, and more.

Contact ProTek Models today to learn how our state-of-the-art 3D print can help your business achieve its sustainability goals. You can reach us online through our website or call us at (832) 968-6636 to speak to a member of our design team.